Sync Options for PFD Worksheets

In the software, there are several ways that a PFD worksheet, process FMEA and control plan can be used together to document a manufacturing or assembly process. In this topic, we will describe the sync options available and provide some recommendations.

Note: The descriptions in this topic are based on the default names of the fields. Your worksheet may have different fields depending on the interface style settings that have been defined for the current project. If you have the permissions necessary to edit the project properties, you can enable, hide or rename any of the fields in the worksheets that are part of the synchronization process via the Interface Style window.

General Sync Workflow

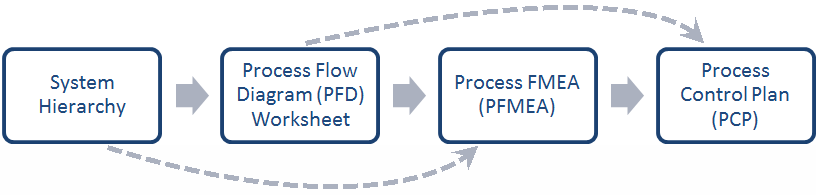

The synchronization functionality is intended to provide you with a starting point for a new analysis by copying relevant data. In general, the information flows as shown below (the dotted arrows represent alternative sync actions).

Note: When syncing data, the data are copied, not linked. Changes made in one analysis worksheet do not automatically appear in the related worksheets and vice versa.

Generally, the system hierarchy is synced with the PFD worksheet, which is then synced with the PFMEA. The PFMEA is then synced with the PCP. The main advantage of the general sync workflow is that you’ll be able to track each process step across all worksheets via the reference numbers (operation sequence numbers). For example, process step #1.2.5 in the system hierarchy will have the same reference number in the PFD worksheet, PFMEA and PCP. In addition, the same operation descriptions will be copied across all worksheets. You’ll have the option to edit the descriptions after each sync process, if desired.

The software offers alternative sync workflows and several options for choosing which data to sync in each worksheet. Your sync approach may vary depending on how your organization performs the analyses. The following sections describe the available sync options for each worksheet.

Sync with PFD Worksheet

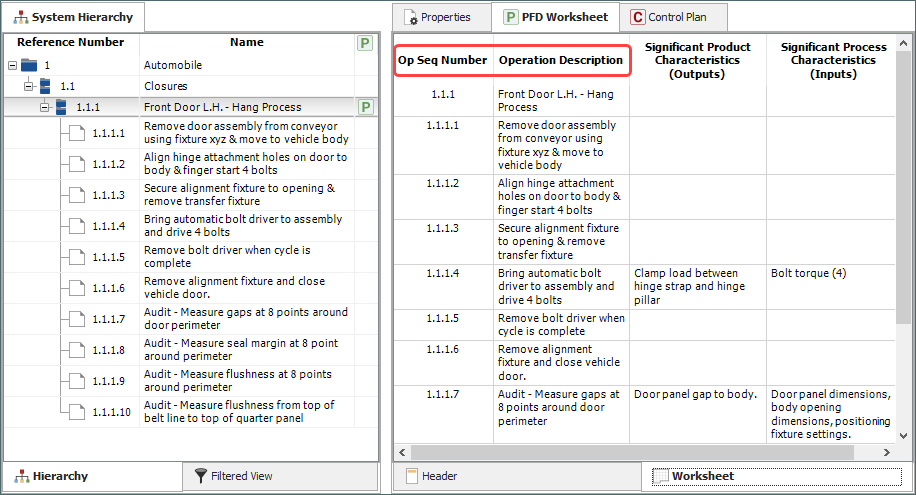

The PFD worksheet is always synced with the system hierarchy. This means that when you create a new PFD worksheet for a top-level item, the descriptions and reference numbers of all its dependents are automatically copied to the relevant fields in the new PFD worksheet, as shown in the following example. This provides you with a starting point for filling out the rest of the PFD worksheet.

Sync with PFMEAs

You can choose to start with a blank PFMEA or with data imported automatically from either the PFD worksheet or the system hierarchy. The settings are configured via the FMEA > Sync Options page of the Interface Style window.

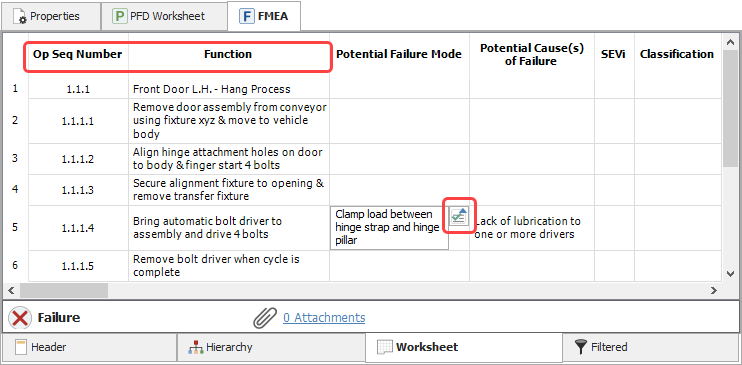

Sync with PFD worksheet - Uses the operation descriptions in the PFD worksheet to populate the function description fields in the new PFMEA. You might select this option if you want the same descriptions for both fields. Special care with the wording of the descriptions may be required in order for them to make sense within the context of each worksheet. Alternatively, you can opt to edit the descriptions after the sync.

Or

Sync with system hierarchy - Uses the item descriptions in the system hierarchy to populate the function description fields in the new PFMEA. You might select this option if you prefer to use a graphical process flow diagram or other analysis method, instead of the PFD worksheet.

The following example highlights the FMEA columns that can be automatically populated by the sync process. In addition to the automatic sync, you can use the Select Existing icon (also highlighted) to manually copy selected product and process characteristic descriptions in the PFD worksheet to the failures and causes fields in the PFMEA, if desired.

Sync with Control Plans (PCPs)

You can choose to start with a blank control plan or with data imported automatically from either the PFMEA or PFD worksheet. The settings are configured via the Control Plan > Sync Options page of the Interface Style window.

Sync with PFMEA - Uses the function, cause, classification and control descriptions in the PFMEA to populate the operation description, characteristics, classification and control method fields in the new PCP. (Alternatively, if you prefer to sync with the item descriptions in the system hierarchy, choose the Transfer from Items option in the Control Plan > Sync Options page of the Interface Style window.)

Or

Sync with PFD worksheet - Uses the operation descriptions and characteristics defined in the PFD worksheet to populate the relevant fields in the new PCP. You might select this option, for example, if you use the PFD worksheet to define the key product and control characteristics (KPCs and KCCs) of the process steps that are currently in place, and then use the PFMEA to analyze subsequent changes to the process steps, with new KPCs and KCCs being identified. In this case, syncing the PCP with the PFD worksheet provides continuity to the analyses of the KPCs and KCC identified in the PFD worksheet.

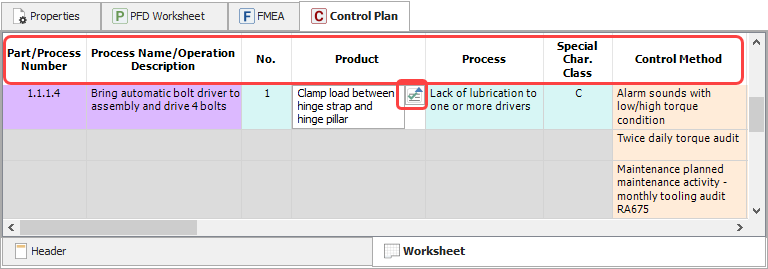

The following example highlights the PCP columns that can be automatically populated by the sync process. (Note that the Control Method column can be synced only with PFMEAs.) In addition, you can use the Select Existing Text icon (also highlighted) to manually copy text from either the PFD worksheet or PFMEA, if desired.

In the PCP, you can use the Select Existing icon to:

Copy selected functions and control descriptions in the PFMEAs to the operation description and control method fields in the PCP.

Copy selected failure and cause descriptions in the PFMEA to the product and process characteristics fields in the PCP.

Copy selected product and process characteristic descriptions in the PFD worksheet to the product and process characteristics fields in the PCP.