Single-Stress Example

For life-stress data only.

A manufacturer asks a team of engineers to determine, with a confidence level of 90%, whether a prototype device has a reliability of at least 90% at 6,000 hours. Since the life of the product under normal operating conditions is expected to be more than 15,000 hours, it is not feasible to test under these conditions and obtain results in an acceptable timeframe. So the engineers decide to run an accelerated test with a duration of 7,500 hours, by which time they expect that the majority of units will have failed. The normal operating temperature for this product is 323 K (50°C), and temperature is the only acceleration variable.

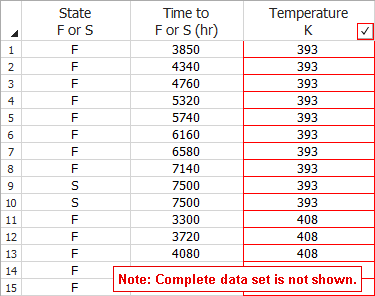

The data collected from the test for three different accelerated stress levels are shown next.

|

Stress Level (K) |

393 |

408 |

423 |

|

Failure Time (Hr) |

3850 |

3300 |

2750 |

|

4340 |

3720 |

3100 |

|

|

4760 |

4080 |

3400 |

|

|

5320 |

4560 |

3800 |

|

|

5740 |

4920 |

4100 |

|

|

6160 |

5280 |

4400 |

|

|

6580 |

5640 |

4700 |

|

|

7140 |

6120 |

5100 |

|

|

Did not fail |

6840 |

5700 |

|

|

Did not fail |

Did not fail |

6400 |

Create a Life-Stress Data Folio

- Choose Home > Insert > Life-Stress Data. On the first page of the setup window, make sure only the My data contains units that did not fail (suspensions/right censored data) check box is selected. Then, select Hour (hr) from the Units drop-down list and click Next.

- On the second page of the setup window, select Temperature as the stress type. Set the use level temperature to 323 with K as the unit. Click OK to create the folio.

- Enter the given data in the data sheet. The first fifteen rows of the data sheet are shown next.

Analyze the Data Set

- On the Main page of the folio’s control panel, select the Arrhenius-Weibull model and click the Calculate icon. The parameters of the model will be automatically computed and displayed in the Analysis Summary area of the control panel.

![]()

- To estimate the reliability of the device at 6,000 hours, click the Quick Calculation Pad icon on the control panel.

![]()

- In the QCP,

choose to calculate the Reliability

with Lower One-Sided

confidence bounds. Select Hour

for the time units and then make the following inputs:

- Stress = 323

- Mission End Time = 6000

- Confidence Level = 0.90

- Click Calculate to display the results, as shown next. The results show that the device’s estimated reliability at 6,000 hours is 99.09%. The lower one-sided 90% confidence bound is shown to be 90.61%. In other words, the test shows with 90% confidence that the device’s reliability a 6,000 hours is at least 90.61%, thus meeting the demands of the manufacturer.