Non-Operational Properties

The MIL-217 standard assumes that all the items in the analysis are operating under normal conditions (i.e., with the power on and performing its intended function). There are, however, systems and assemblies in which the non-operating time represents a significant portion of the useful life (e.g., missiles, fuses, projectiles, etc.).

Lambda Predict provides an optional tool that allows you to obtain the non-operating failure rate. This tool is based on the technical report, RADC-TR-85-91 (Impact of Non-Operating Periods on Equipment Reliability), which was produced in 1985 for the U.S. Air Force. The non-operating failure rate models provided by the report are patterned after the failure rate models in the MIL-217 standard, and can be used to separately predict the non-operating failure rates of components or to complement the MIL-217 analysis.

To access the tool, select the item in the system hierarchy and choose Prediction > MIL-217 > Non-Operational.

![]()

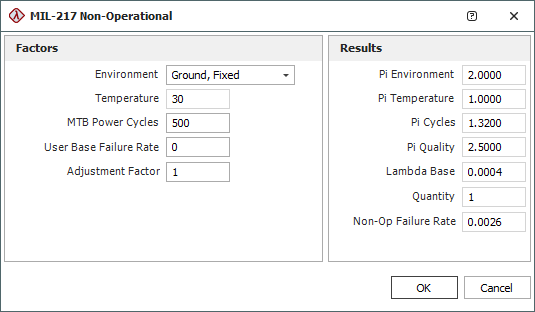

The Factors area contains the properties that must be defined to calculate the non-operating failure rate. The list of properties varies depending on the item being analyzed. If a property is unavailable, this indicates that the property is specified at another level. For example, for a capacitor, the Temperature property will be unavailable because this property needs to be specified at the block level (![]() or

or ![]() ).

).

Lambda Predict also includes two properties that are available regardless of which item is being analyzed:

- User Base Failure Rate allows you to directly enter the non-operating base failure rate of the item. This is useful for analyzing specific items that are not covered by the RADC report.

- Adjustment Factor allows you to tweak an item's calculated non-operating failure rate by a specified value. For example, if you have reason to believe that the non-operating failure rate of a component will be half of the rate calculated by the application, change the adjustment factor from 1 (the default) to 0.5. If you expect that the failure rate will be twice what would be calculated by the application, change it to 2, and so on. Assuming that the calculated non-operating failure rate is 0.1544, the software would display 0.0772 with an adjustment factor of 0.05, or 0.3087 with an adjustment factor of 2.

The Results area displays the calculated pi factors of the item's non-operating failure rate model. This makes it possible to directly see how the inputs affect the calculations. For example, if you are working with a capacitor, the RADC report provides the following non-operating failure rate model:

As shown next, the Results area calculates the pi factors based on your inputs, where Lambda Base = λNB,Pi Environment=

If you are working with a block, the Update Dependents check box will be available. Select this check box to apply the same non-operating environment, temperature and mean time between power cycles properties to the block's sub-items. Note that any subordinate blocks are not updated until you click OK, so the values shown in the Results area do not yet take into account the effect of the change that will be applied to the sub-items.

Analysis Results for Non-Operating Conditions

When you specify non-operational phases, you can display the following results in the system hierarchy. (To hide or display the columns in the system hierarchy, right-click the column headings, and then click Customize Columns to select which columns you want to display. These settings are stored per computer/username on the System Hierarchy page of the Application Setup, so any project that you open on this computer will have the same columns displayed.)

- Non-Operational Failure Rate

- Non-Operational MTBF

- Non-Operational Contribution