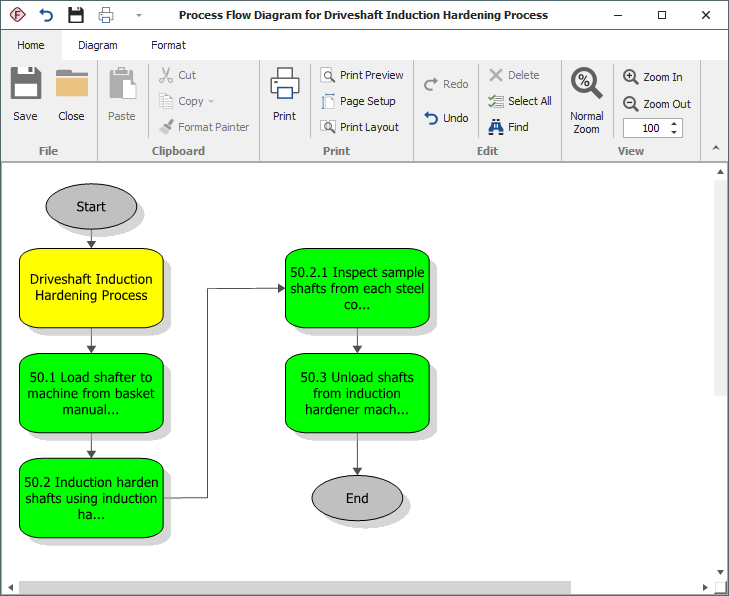

Process Flow Diagrams

You can create a process flow diagram for any item in the system hierarchy. These diagrams are high level charts that help you to visualize the steps that a product goes through in a manufacturing or assembly process.

Tip: If you want to use the process flow diagram as a starting point for preparing process FMEAs (PFMEAs) or control plans, then the PFD worksheet may be a more appropriate tool. The PFD worksheet integrates the chart into a worksheet that records more detailed information about each step in the process and it allows you to synchronize the relevant information with the PFMEA or control plan analysis. (See PFD Worksheets.)

To create a new process flow diagram (or open or delete a saved one), select an item in the System panel then choose System Hierarchy > Current Item > Diagrams > Process Flow Diagram. You can also right-click the item and choose Diagrams > Process Flow Diagram.

![]()

If a diagram has already been saved for the current item, you will be prompted to open, delete or replace it.

When you are creating a new process flow diagram, the Create Process Flow Diagram window gives you the option to start with a blank diagram or generate blocks based on the item’s FMEA or control plan. Specifically:

Based on system hierarchy creates blocks for the selected item and any sub-items.

Based on system hierarchy and FMEA functions creates block for each function in the FMEA for the selected item, as well as any sub-items.

Based on control plan creates a block for each Process Name/Operation Description in the control plan associated with the selected item. This option is available only if the selected item has a control plan; it does not consider any control plans that may be present for sub-items.