RBI Background

The American Petroleum Institute (API) recommends to develop an inspection program using risk-based methods. You can use ReliaSoft RBI to record the data relating to the potential damage to specific equipment and components, and then forecast future physical and economic consequences of failure as well as the probabilities of failure for individual components, equipment and entire plants. In addition, you will be able to better plan when to inspect, maintain and replace weak components before failure occurs.

The program is primarily based on two publications: API RP 580 and API RP 581. Both provide guidance on developing a risk-based inspection program for fixed equipment in refining, petrochemical and chemical process plants. The documents are written to include RBI methods for pressurized fixed equipment such as pressure vessels, piping, tanks, pressure relief devices and heat exchanger tube bundles, among others.

Note: RBI corrects several errors that are present in the API RP 580 and API RP 581 standards so the results obtained in the RBI software may differ from those calculated using other methods. These changes included correcting several property values in tables (e.g., the nominal boiling point of NO2 is 22°C and not the 135°C shown in the standard), correcting inconsistencies in equations and correcting some theoretical inconsistencies.

Introduction

The RBI software calculates the probability of failure and the consequence of failure for given components in a pressurized environment. These calculations are used to help plan inspections and reduce the risk of failure.

The API defines failure as the loss of containment from a pressure boundary resulting in leakage to the atmosphere or a rupture of the pressurized component. Throughout a given period of time, damage will accumulate within a pressured environment. That damage causes increased risk of failure to equipment and components. After a significant amount of damage, a predetermined risk target is exceeded and an inspection of that component is recommended to better understand and measure the damage.

Consequences of Failure

Within RBI, there are two types of consequence analyses: area and financial. The loss of containment by leakage, rupture or other causes can cause damage to nearby equipment, the environment and/or be harmful to personnel. Some components must have both types of consequence analysis performed, while others do not. The consequence properties help to rank components based on risk.

The consequence analysis in the RBI software is modeled after API RP 581’s Level 1 consequence analysis, which is a method used to evaluate the consequences of fluid or gas release.

Probability of Failure

In an RBI assessment, the probability of a component failing is based on several factors:

-

Each component has its own set of internal properties including its generic failure frequency (GFF), which is the frequency of failure prior to any specific damage occurring from exposure to the operating environment. The RBI software calculates the GFF value using four different damage hole sizes and uses adjustment factors to reflect departures from industry data and to account for damage within a given component’s normal operating environment. Hole sizes are Small, Medium, Large and Rupture.

-

The Management Systems Score is an adjustment factor that accounts for the management influence of a given plant’s supervisors and management on the mechanical integrity of the plant equipment. This factor helps to measure how likely it will be that management finds issues related to the plant’s mechanical integrity. The factor is calculated based on a Management Score Survey that evaluates the facility’s management systems and their effect on a given plant’s risk.

-

Each Damage Factor is determined in accordance with API RP 581 and is based upon damage mechanisms relevant to construction, process services, current condition and prior damage inspections. According to API 581, the purpose of these damage factors is to provide a way to statistically evaluate the amount of damage that may be present as a function of time in service and effectiveness of an inspection activity to quantify damage.

Program Parts

The API RBI program can be broken down into three parts:

-

Determining the Management Score.

-

Defining the probability of failure in an RBI Assessment.

-

Modeling the consequences in API RBI.

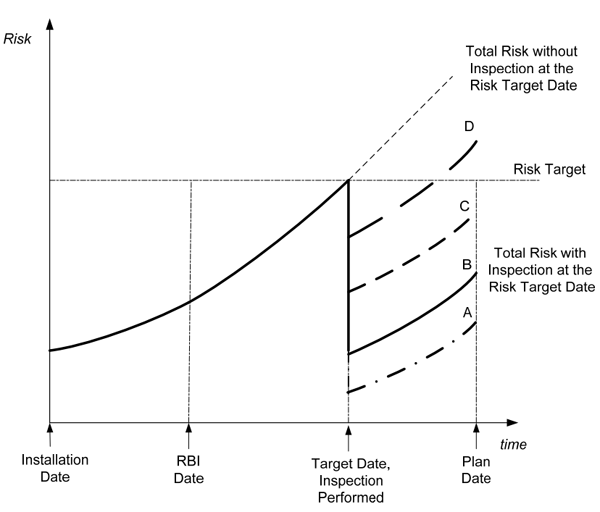

Date Definitions

In a risk based inspection, the following dates are used:

-

The installation date is the date the component was installed or replaced. This is set on the General Properties tab.

-

The plan date is the next date when the component is scheduled to undergo major maintenance or replacement. It is also set on the General Properties tab.

-

The RBI date is the date when you perform the calculations. This is displayed on the Results tab.

-

If the RBI analysis indicates that inspections are needed before the plan date, then the target date is the date when the inspections should be performed to reduce the risk to an acceptable level on the plan date. It is also displayed on the Results tab.

The following graphic shows the risk vs. time curve (i.e., the risk increases as time increases). When you perform an inspection, the risk should go down.