Life Data Degradation Analysis Example

The data set used in this example is available in the example database installed with the Weibull++ software (called "Weibull22_Examples.rsgz22"). To access this database file, choose File > Help, click Open Examples Folder, then browse for the file in the Weibull sub-folder.

The name of the project is "Degradation - Crack Propagation."

An analyst needs to determine the time when 10% of the turbine blades in a sample are expected to fail (i.e., B10 life). To determine performance, the blades are tested for crack propagation. The units are cyclically stressed and inspected every 100,000 cycles for crack length. Failure is defined as a crack length of 30mm or greater.

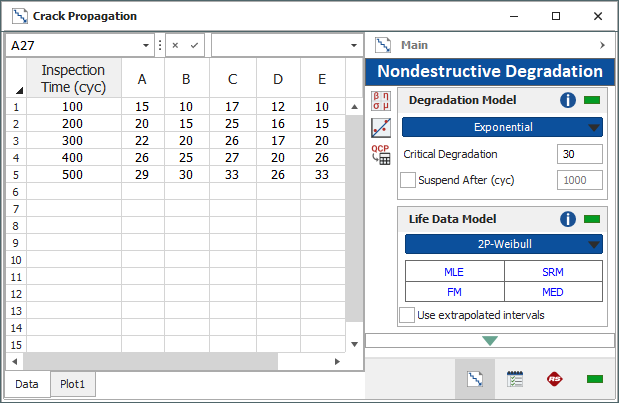

The data sheet in the "Crack Propagation" folio displays the results of the inspections for the five units, A through E.

Using degradation analysis, project the failure times for the blades using an exponential model for the extrapolation, and then calculate the reliability of the blades at a 90% confidence level.

Analyze the Data Set

- The first step is set up the data sheet for the analysis. Click the Change Units icon on the Main page of the control panel

![]()

- In the Change Units window, select to change the time units to Cycles.

- On the control panel, select the Exponential degradation model and enter a value of 30 for the Critical Degradation.

- For the life data model, select the 2P Weibull distribution and the MLE analysis method. Use the default settings for all other options, as shown next.

- Click Calculate and then click the Plot icon on the Main page of the control panel.

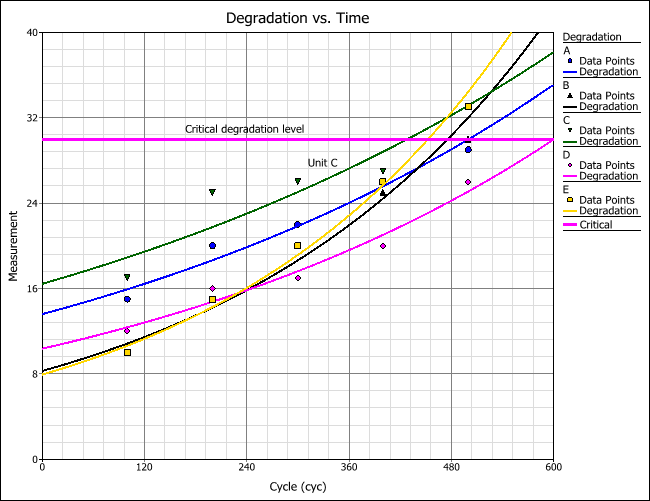

The Degradation vs. Time (Linear) plot shows that unit C is expected to reach the critical degradation level first, compared to the other units. (Plot shown with annotations to make the information easier to read.)

- To view the times when the units will reach the critical degradation level, return to the data sheet of the folio. On the control panel, click the Degradation Results (...) button. In the Results window, select the second data sheet. The report shows that Unit C will reach critical degradation at about 428.74 cycles.

- To view the results of the life data analysis, close the Results window and click the Life Data Results (...) button on the control panel. The parameters of the life data model are estimated to be beta = 8.055074 and eta = 519.555393.

Estimate the B10 Life

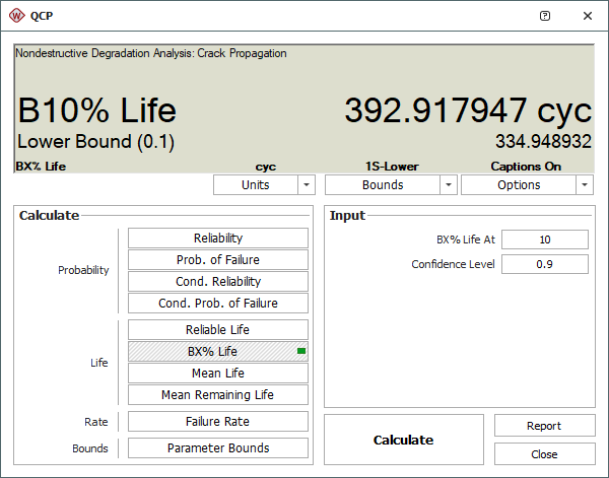

- The next step is to estimate the time when 10% of the blades in the sample are expected to fail. Close the Results window and click the QCP icon on the control panel.

- In the QCP, choose to calculate the BX%

Life with lower 1-sided

confidence bounds. Select Cycles

for the units and then make the following inputs:

- BX% Life At = 10

- Confidence Level = 0.9

- Click Calculate nto obtain the results. The results indicate that 10% of the turbine blades will have failed (i.e., B10 life) at approximately 392.92 cycles of operation, and the 90% lower one-sided confidence bound on the B10 life is 334.95 cycles.