Parametric RDA Folio

The parametric RDA folio uses the General Renewal Process (GRP) model to analyze the failure behavior of a repairable system. The GRP analysis method takes into account the effectiveness of repairs on the condition of the system. For example, a repair may bring the system to an as-good-as-new condition, to an as-bad-as-old condition or to some stage in between. If the system is only partially rejuvenated after the repair, then this may affect how the system fails in the future. Over time, the recurrence rate of failures may remain constant, increase or decrease. The GRP model allows you to analyze the failure behavior of a partially restored system over time so you can obtain estimates such as the cumulative number of failures, mean time between failures (MTBF) and failure intensity. The ReliaWiki resource portal has more information on the GRP model at: http://www.reliawiki.org/index.php/Parametric_Recurrent_Event_Data_Analysis.

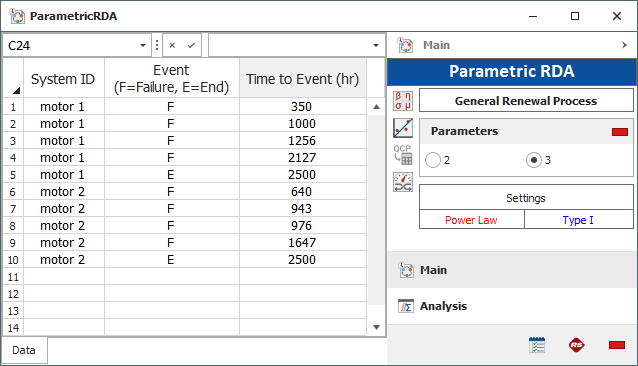

Parametric RDA Data Sheet

To create a parametric RDA folio, choose Home > Insert > Parametric RDA, or right-click the Repairable Systems folder in the current project explorer and choose Add Parametric RDA on the shortcut menu.

![]()

The following picture shows an example of a parametric RDA folio data sheet.

The System ID column identifies the system that experienced an event. In the sample data sheet, two units of the same type of motor are being tracked. The results, such as the mean time between failures (MTBF) and failure intensity, will depict the average behavior of the motors.

The Event column describes the type of event. An F indicates a failure event and an E indicates that the observation period for the unit has ended. Each unique system in the data sheet must have a single end event. If you do not enter an end event for a system, then the end event is assumed to be equal to the last failure time for that system. In addition, the data set must have at least three failures in order for the software to perform the calculations.

Notice that the repair times of the motors are not recorded in the data sheet. This is because the GRP model assumes that the repair times are negligible and only the effects of the repairs on the condition of the system are of concern. Therefore, each data point in the data sheet can be treated as a single fail-and-repair process.

The Time to Event column indicates the age of the system when the event occurred. For each unique system, the time of the end event (E) must be equal to or greater than the last failure time of that system. The time of the end event is also known as the censoring age, because the product’s failure or repair history beyond that time is unknown.