Systems and Powerplant Analysis Tasks

The Task Properties window allows you to view/edit all of the properties for a particular maintenance task. For aircraft systems and powerplant analysis, there are several ways to access this window:

- Double-click a task record in the F-F-E-C hierarchy or filtered view.

- Open the Task Selection window for a particular failure cause and then either double-click one of the records in the Assigned Tasks table or click Edit Task on the ribbon.

The following properties are available for tasks that are recommended based on a systems and powerplant analysis:

Note: Some of the properties can be enabled or disabled depending on your requirements. You can choose Systems > Tools > Configurable Options to open the Configurable Options for Systems and Powerplant Analysis window and change the settings for the current project.

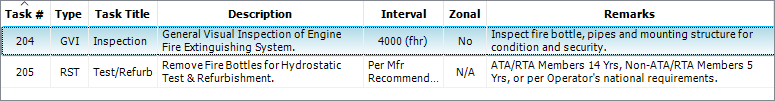

- Together, the Group # and # fields form the unique identification number for the task. You have the option to organize tasks into up to ten groups, and when you select a group number from the drop-down list, the # field will be set automatically to the next number in the sequence for the selected group. For example, if the new task belongs to Group 3 and two other tasks have already been created for Group 3, the unique identification number for the new task will be Group 3, Task 3. If you do not want to organize tasks by group, you can simply accept the default group number for all new tasks (which is set in the MPC Application Setup).

- The Task Title field allows you to provide more information about the task. This field is used only in the Standard report template.

-

The Task Type field allows you to specify the type of maintenance task by choosing from a drop-down list. This cannot be changed after you have saved the task. Note the following:

- Although the options in the drop-down list are determined by the requirements of the MSG-3 guidelines, the abbreviations can be modified, if desired. (See Task Type Abbreviations in MPC.)

- If no other tasks have been defined for the current cause, the No Task Selected (NTS) option will appear at the bottom of the drop-down list. When you select this option, all of the task properties (except the Task drop-down list) will be disabled. You will not be able to add any other maintenance tasks for this cause without first deleting the NTS record.

- When you attempt to close the Task Selection window, MPC will check to make sure that the assigned tasks are consistent with the answers for the MSG-3 task selection questions (e.g., if you answered Yes to the first question, a task with the Lubrication or Service task type must be assigned).

- The Task Description field allows you to provide more information about what the task is designed to do. Note that if the Task Type is "No Task Selected" then the field becomes a drop-down list where you can select an option that explains why no task has been selected for this cause.

- When using the Revision 2018 Vol 2 MSG-3 guideline, the HUMS Certified field is available for Scheduled Health and Usage Monitoring tasks. This field allows you to specify that the task is certified for credit for the concerned failures and can be used in place of a Functional Check task.

- Interval Info

- For Sources of Information, you can select one or more of the predefined options from the drop-down list and the Interval Comments field allows you to record any additional notes about the source. This information is displayed in the "Interval Substantiation" section of the Dassault report template and is not applicable for the Standard or Sukhoi templates.

-

For Interval Type:

- Select Fixed (Numerical) if you want to the interval to be recorded as a number with an associated unit (e.g., 2,000 flight hours can be stored as value = 2000 and unit = FHr). Numbers may be easier to sort and will also make it possible to perform simulation-based reliability calculations if you choose to import the analysis project to RCM++.

- Select Based on Events (Text) if you want the interval to be stored in a text field, which can contain any combination of letters or numbers (e.g., "Per Mfr Recommendation").

-

For Interval:

- If you choose to enter a number, the field will be split into two sections so you can enter the time and then select the units from the drop-down list. The options in the drop-down list can be modified. (See Unit Settings.)

- If you choose to store the interval as text, you can type up to 100 characters into the field.

- Zonal

- ZIP Candidate allows you to select (Yes or No) whether the task should be considered for transfer into the zonal inspection plan (ZIP). If "Yes" the task will be available for a standard zonal analysis using the Transfer Zonal Candidate Tasks feature.

This field is available only if the failure effect categorization (FEC) value is 5 or 8 (i.e., a safety issue) and the task type is "General Visual Inspection (GVI)".

- Zone allows you to specify where in the aircraft the relevant part is located (i.e., the zone where the task will occur). While you can use the same numbers as used in the zonal analysis, this is not required.

- Other

The following fields are used only in the Standard report template:

- Use the Manual Reference field to record additional information about the task, such as where in your maintenance procedures the task is described.

- Use the Remarks field to record any additional the remarks about the task.

The following fields are used only in the Standard and Dassault report templates:

- Use the Effectivity field to record additional information about the task, such as how effective the task is designed to be when performed.

- Use the Access field to record the type of access that will be required in order to perform the task.

The following fields are used only in the Dassault report template:

- Use the Ground Support field to record any additional information about the ground support requirements associated with the task.

- Use the Procedure field to record additional information about the procedure used to complete the task.

- The Associated Records area displays the analysis context for the record. In the Task Properties window, this includes the specific cause, effect, failure, function and MSI that the task is associated with.

-

History provides information about when the record was created and last updated. If the history log has been activated at the project level, you can click the View Item History icon to open the Record History Log for the record.

![]()

-

Watch allows each individual user to subscribe to receive an alert (via e-mail, SMS text message or portal message) when the resource is changed.