Using Mixture Designs in DOE++

In design of experiments, a mixture is defined as a product that is formed by mixing together two or more individually distinct ingredients, known as the mixture components. In some cases, the properties of the mixture are only dependent on the components and their proportions, and not on the amount of the mixture. For example, one cup of 10% hydrogen peroxide solution in water has the same properties as one gallon of 10% hydrogen peroxide solution in water. In other cases, outside influences such as process variable settings can affect the properties of the mixture as well. For example, the viscosity of a polymer solution will depend not only on the concentration of polymer in the solution, but also the mixing speed because higher speeds can break the polymer chains, leading to shorter chains and therefore a lower viscosity of the mixture. In this article, we describe the four common mixture designs followed by an example using DOE++ that illustrates how to create a mixture design.

Design Types

There are four common designs used for mixtures: simplex lattice, simplex centroid, simplex axial and extreme vertex. Each mixture design is used for a specific purpose, as described in the following sections.

Simplex Lattice Design

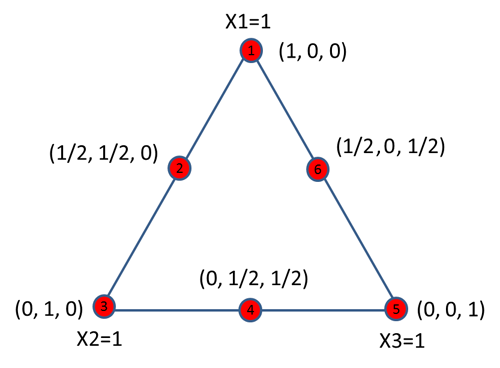

The simplex lattice design is useful for a small number of components with response surfaces that need a polynomial equation of order 2 or greater for an accurate description. In this design, the points are spread evenly over the whole simplex. For example, a mixture with 3 components could have a design that looks like this:

Simplex Centroid Design

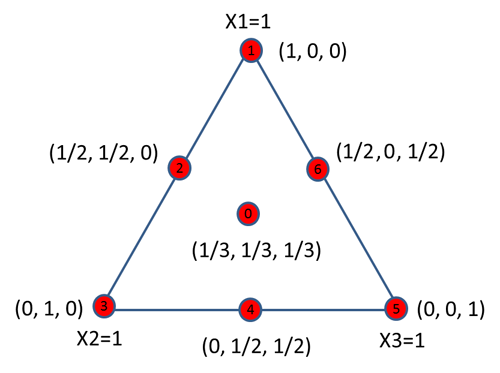

The simplex centroid design can be used for the same purpose as the simplex lattice design or it can be used to identify the important components in a mixture that contains a large number of components. In this design, only the centroid points are included. A 3-component mixture design could look something like this:

Simplex Axial Design

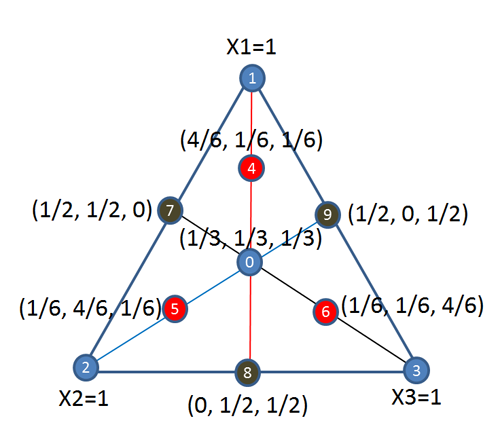

The simplex axial design is mostly used to identify the important components in mixtures that contain a large number of components. While the simplex lattice and simplex centroid designs are boundary designs where all the points are on the boundaries except for the overall centroid, the simplex axial design also consists of points positioned inside the simplex. A simplex axial design for a 3-component mixture could look like this:

Extreme Vertex Design

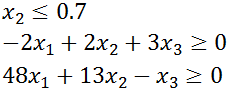

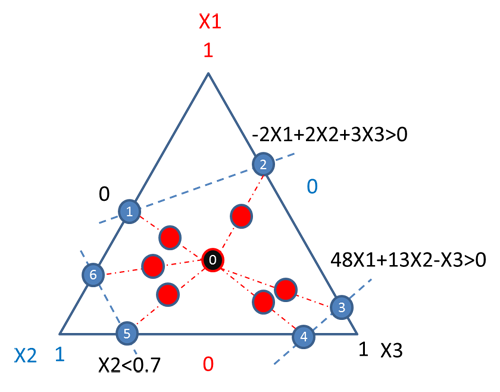

The extreme vertex design is used when there are constraints on one or more components of the mixture (such as a minimum and/or a maximum concentration of a component) or when there is a linear constraint on several components. In this design, the constraints define the area of the factor space that can be used, usually with the boundary points used as the default run settings. For example, with the following constraints:

the factor space and available area would look like this:

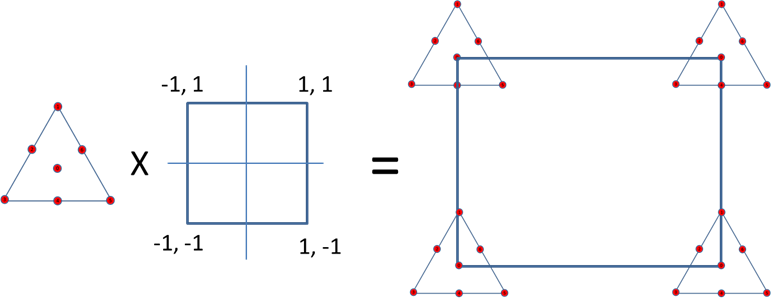

Mixture Design with Process Variables

In cases where process variables also contribute to the mixture properties, the mixture experiment has to be conducted in a way as to test for the effects of the process variables. The easy way to do this is to create a design where we do our mixture design at each location generated for our process variables based on a design for those, such as a standard factorial design. For example, if we have a 3-component mixture, for which we would use a simplex lattice design with a center point, where 2 independent process variables are also significant, we could create the following design:

In this case, the simplex lattice design gives us 7 points, and performing each of those at the 4 combinations for the process variables ends up giving a total of 28 points in the design.

Example

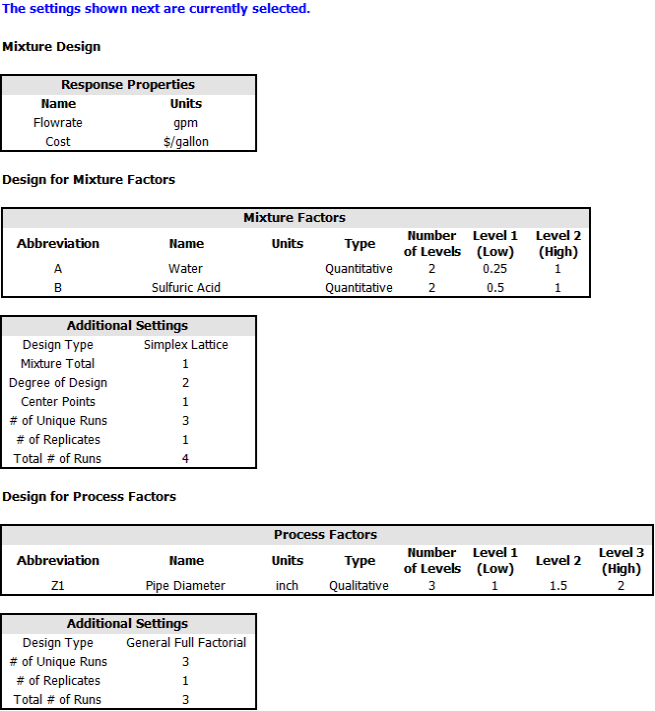

We are trying to optimize a process flow containing sulfuric acid in order to minimize our costs and still be within the required specifications. The specifications are that the concentration of the water has to be at least 25 percent and that of the sulfuric acid has to be at least 50 percent. We must also have a flow rate of 40 gallons per minute, give or take 2 gallons per minute, and we would like to minimize our cost per gallon as well. We know that the acid concentration and the pipe diameter affect both the flow rate and the cost of flow.

Overall, we have a mixture with 2 components (water and sulfuric acid), 1 process variable (pipe diameter) and 2 responses (flow rate and cost). We will use a simplex lattice design for our mixture components; however, we will set the degree of design to 2 because we are fairly certain that the acid concentration and the flow rate do not follow a linear relationship. For the single process variable, we need to use the general full factorial design because we have only 1 variable and we want to test it at our 3 possible levels. The design summary in DOE++ looks like this:

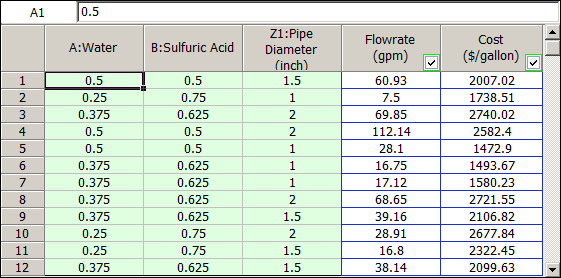

After generating the design, we input the responses shown next:

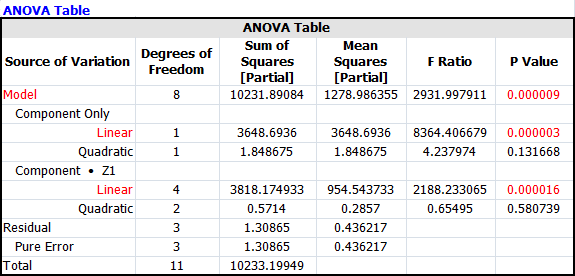

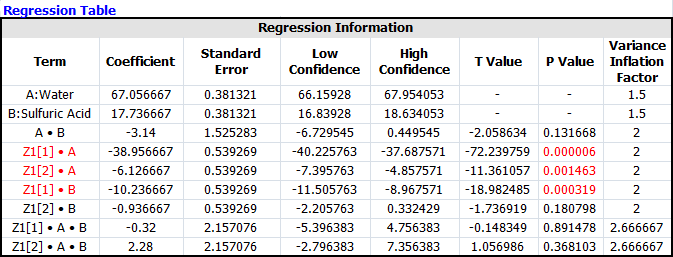

After running the analysis, the ANOVA table and the regression table are:

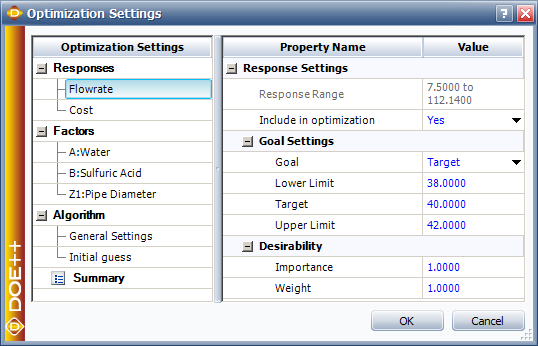

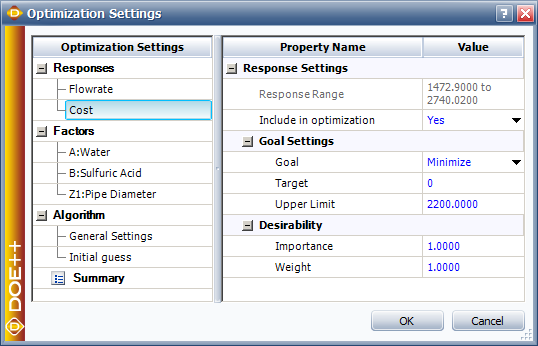

Since our end goal is to have our specified flow rate with a minimal cost, we use the optimization tool where we specify our requirements:

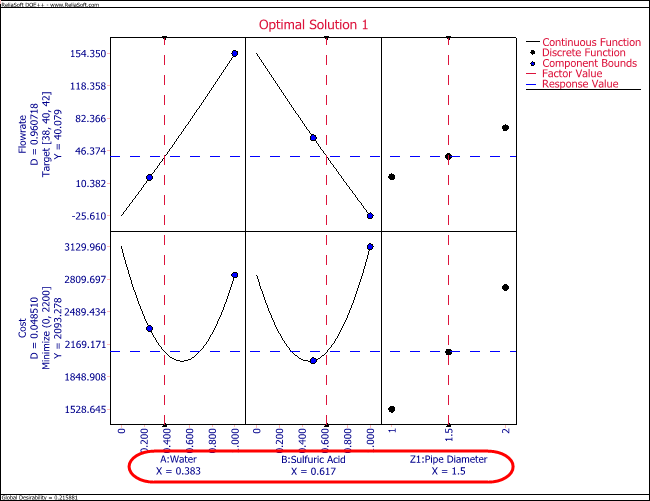

The optimization tool displays the following plot to show us the calculated interaction between our variables and requirements and our optimal settings used to obtain our goals:

Based on these results, we should be using a 1.5 inch diameter pipe and our solution should be 61.7% sulfuric acid. This gives us the flow rate that we are looking for at the lowest cost.

Conclusion

In this article, we saw how we can use the mixture design methodology found in DOE++ to optimize the responses we need based on both mixture properties and process factors.