Calculating Equivalent Acceleration Factors for Random Stresses

In accelerated life tests, when a component has been tested for a number of hours under the stressed condition, we want to know the equivalent operation time at the use stress condition. If the use stress is a constant value, this is easy to calculate. However, a stress at the use condition is usually random, so how can we calculate the equivalent acceleration factor for a random stress? In this article, we will illustrate one simple method.

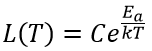

Let's assume the stress is temperature. The following Arrhenius model is used:

|

(1) |

where:

- L(T) is the life at a temperature of T [h]

- C is a scaling constant [h]

- Ea is the activation energy [eV]

- k is Boltzmann’s constant (8.617 x 10-5 eV/K)

- T is the temperature [K]

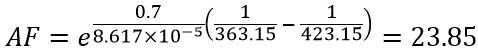

If the use condition temperature is TU and the accelerated temperature is TA, then the acceleration factor (AF) can be calculated by:

|

(2) |

It can be seen that we only need to know the value of Ea in order to calculate AF, if Ta and Tu are provided. If Ea is unknown, it can be estimated from a quantitative accelerated life test using at least two different temperature levels. For more details on quantitative accelerated life data analysis, please see the Accelerated Life Testing Reference.

Consider a situation where the use stress is constant. Assume Ea = 0.7 eV, TA = 150 C (423.15 K) and TU = 90 C (363.15 K). Then, the AF is:

|

(3) |

Therefore, 1 hour of testing at the accelerated temperature is equivalent to 23.85 hours at the use condition.

Now, for a situation where the use stress is not constant, let's use a simple example to examine how the equivalent acceleration factor and test time can be calculated. Assume the use stress is random and can be quantified using the following table.

| Temperature (C) | Temperature (K) | Probability |

| < 20 | < 293.15 | 0.05 |

| [20, 40] | [293.15, 313.15] | 0.70 |

| [40, 50] | [313.15, 323.15] | 0.20 |

| > 50 | > 323.15 | 0.05 |

Consider a demonstration test in which 10 components are tested for 500 hours at a temperature of 90 C (363.15 K) without failure. What is the equivalent number of hours under the use condition, and what is the demonstrated reliability at the use condition? A simple way to determine this is to calculate the AF for each temperature range. Let's assume that we have prior engineering knowledge that Ea = 0.92. Using Eqn. (2), the calculated AFs are:

| Temperature (C) | Temperature (K) | Probability | AF |

| < 20 | < 293.15 | 0.05 | 1119.1 |

| [20, 40] | [293.15, 313.15] | 0.70 | 336.6 |

| [40, 50] | [313.15, 323.15] | 0.20 | 64.0 |

| > 50 | > 323.15 | 0.05 | 38.1 |

Note: For each temperature range, the middle point is used for the AF calculation.

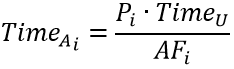

If the total time at the use condition is TimeU, then for the ith temperature range the corresponding time at the accelerated condition TimeAi is given by:

where Pi is the probability of the use temperature being in the ith temperature range. Then the equivalent total time at the accelerated condition is given by:

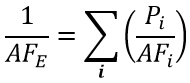

Next we define the equivalent AF as:

|

Then:

|

(4) |

For the case in the table above AFE = 152.47. Therefore, 500 hours of testing at a temperature of 90 C is equivalent to 500 x 152.47 = 76,200 hours of operation.

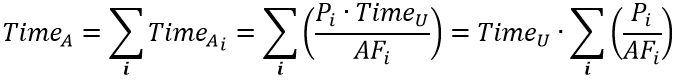

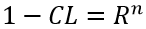

The next task is to determine the demonstrated reliability at the use condition based on the results of the accelerated life test. For a random use stress condition, this question can be answered using the binomial equation for the zero-failure demonstration test:

|

(5) |

where:

- CL is the confidence level

- R is the demonstrated reliability

- n is the number of units on test

For this example, where all 10 units survived a test at 90 C for 500 hours, we can calculate that the demonstrated reliability is 85.13% at a lower one-sided confidence level of 80%. This is the same as saying that the reliability at 76,200 hours under the use condition is 85.13% at lower one-sided confidence level of 80%.

Conclusion

In this article, we discussed how to calculate the equivalent acceleration factor (AF) for a random stress. When the stress at the use condition is random, it can be quantified by its possible ranges and the probability that the use stress falls within each range. The AF for each range can be calculated and the overall equivalent AF will be the weighted average of the AFs from all the ranges. Once the equivalent AF is obtained, the equivalent operation time under the use condition can be calculated. From the sample size, number of failures and confidence level, the demonstrated reliability also can be calculated.

Although temperature and the Arrhenius model are used for illustration in this article, the methods used here can also be applied to other stresses and models.